The Ridge!

"In this Special Series, I document the complete development, fitment and ordering recommendations to the 1:1 CSL carbon diffuser.

This entry documents the backstory to this successful crowdfunding of the 1:1 CSL carbon diffuser, and the little things that matter about it."

-Matt

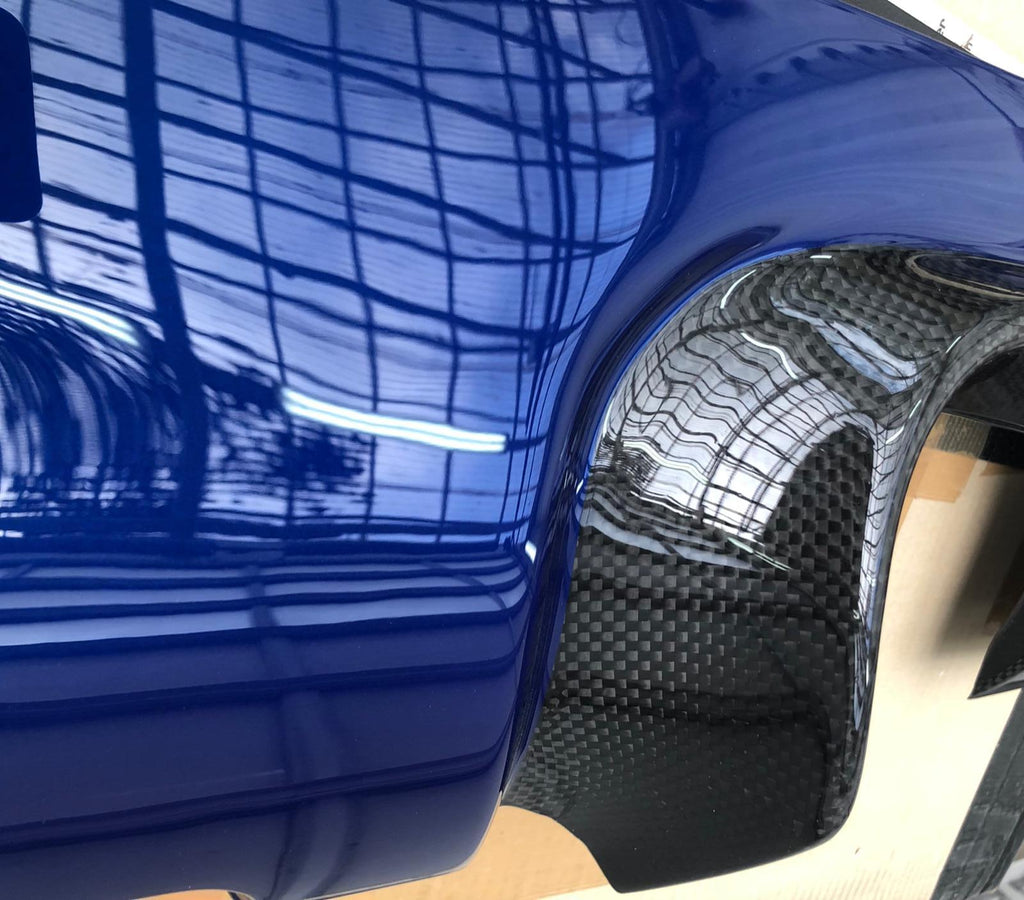

The ridge-less design.

Suppliers of 1:1 CSL carbon diffusers are none existent as of today or others just plain don't have the tooling & data to do it right.

We had a CSL diffuser with a slight design change that smooths out the ridge in between the carbon and painted section to avoid IP issues with BMW in Europe.

It was introduced in 2021 and was fitted by a few members of EuroConnex.

The 1:1 Crowdfunding Project

The project involves opening up a new carbon fiber mold for the production of this design instead of his older slightly different design to avoid IP issues with BMW in Europe. I can go into little details about this: we will not simply be using an OEM CSL diffuser to create a negative mold.

What I can tell you is he had already produced a prototype way back in the days and settled on making the slight design change mentioned above.

The carbon process is the same as OEM: pre-preg carbon cured in autoclave. It also uses the original 1x1 plain weave as used by BMW M on the CSL.

What differentiates this new project from any other CSL diffuser currently available will be it's exact design and fabrication replica to the OEM BMW M3 CSL diffuser in every single design detail.

The learnings from the initial batches

This project will incorporate many of the learnings from the initial batches of the previous CSL diffusers.

Packaging

More foam, more bubble wrapping, more paper, thicker cardboard boxes. It increases shipping & packaging prices a bit.It's a no brainer trade off considering 1/5 of the initial diffusers were trashed UPS and incurred some form of damages to the paint, carbon or mounting clips.

Color Matching is still available

Color matching remains available and is very affordable alternative to getting it painted locally as it fits within the fabrication process. The paint line will be dictated by the ridge unlike his previous design which left more leeway.

Ready-to-Paint Primered

This is for the guys that want complete control over their paint process: preparation, paint line, color matching and paint finish.

Up next: taking you behind the scenes on the various steps to the master mold creation process.